Transmission parts

Category:

The transmission in an automobile is a crucial component of the power transmission system. By changing the gear ratio, it adjusts the engine's output power, maintaining good power performance and fuel efficiency under various driving conditions.

Contact:

Product Details

Automobile Transmission It is an important component in the power transmission system of an automobile. By changing the gear ratio, it adjusts the engine's output power and maintains good power performance and economy under various driving conditions.

1. Gears

Function: Gears are the heart of the transmission and are used to change speed and torque. By combining gears of different sizes and numbers of teeth, various gear ratios can be achieved.

Types:

Main gear: Connected to the engine crankshaft, it transmits the engine's power to the inside of the transmission.

Driven gear: Meshes with the main gear, changing speed and torque to meet various driving needs.

Intermediate gear: Used to change the direction of power transmission or to widen the range of gear ratios.

Material: Usually made of high-strength alloy steel, its hardness and wear resistance are improved by heat treatments such as carburizing and quenching.

2. Shafts

Function: Shafts are important components that support gears and transmit power. They transmit the rotational motion of the gears to the wheels and other transmission components.

Types:

Input shaft: Connected to the engine, it receives the engine's power.

Output shaft: Transmits the power after shifting to the differential or driveshaft.

Intermediate shaft: In multi-speed transmissions, it is used to support the intermediate gears and ensure stable power transmission.

Material: Generally made of high-strength alloy steel, it has excellent fatigue resistance and sufficient strength.

3. Synchronizers

Function: During shifting, the synchronizer matches the speeds of the engaging gears, enabling smooth shifting and preventing impact and damage between gears.

Operating principle: When the driver operates the shift lever, the synchronizer synchronizes the rotational speed of the engaging gears with the rotational speed of the shaft through friction elements (e.g., cone ring and cone hub), after which the gears smoothly engage.

Types: Inertia synchronizers and constant-pressure synchronizers are common.

4. Shift Mechanism

Function: Controls the engagement and separation of gears, enabling switching between different gears.

Components:

Shift fork: Changes the engagement state of the gears by moving the gears or sliding sleeves.

Shift lever: The component operated by the driver, transmitting the operation to the shift fork through a mechanical or hydraulic system.

Shift fork shaft: Supports the shift fork and is used to ensure the accuracy of its operation.

Types: The shift mechanism of a manual transmission mainly relies on mechanical drive, while automatic transmissions achieve shifting through a hydraulic system or electronic control system.

5. Case

Function: The transmission case is the outer shell that encloses the entire transmission, housing and protecting internal components such as gears and shafts, while also providing sealing and lubrication.

Material: Usually made of aluminum alloy or cast iron. Aluminum alloy cases are lightweight and have good heat dissipation performance, but their strength is relatively low. Cast iron cases have high strength but are heavy.

Structure: The case is usually divided into an upper case and a lower case for easy assembly and repair.

6. Bearings

Function: The role of bearings is to support the rotation of the shafts, reduce friction, and ensure the stable rotation of the shafts and gears.

Types:

Ball bearings: Suitable for light or medium loads, they have a low coefficient of friction and high rotational accuracy.

Roller bearings: Suitable for heavy loads or high speeds, they have a high load-carrying capacity.

Installation location: Usually installed at both ends or in the middle of the shaft to ensure the stability and rotational accuracy of the shaft.

7. Lubricating Oil and Oil Seals

Lubricating oil:

Function: Lubricating oil lubricates the gears, shafts, and bearings inside the transmission, reducing friction and wear, and simultaneously playing a cooling and cleaning role.

Types: Usually, dedicated transmission oil is used, which has excellent wear resistance, oxidation resistance, and low-temperature fluidity.

Oil seals:

Function: Oil seals prevent lubricating oil leakage and simultaneously prevent external dust and debris from entering the transmission.

Installation location: Usually installed at the joint between the shaft and the case.

8. Other Parts

Clutch (Manual Transmission Only):

Function: The clutch is used to connect or disconnect power transmission between the engine and the transmission. During shifting, the clutch is disengaged to cut off power and prevent impact between gears.

Composition: It consists of a clutch plate, pressure plate, release bearing, etc.

Planetary Gear Set (Automatic Transmission Only):

Function: The planetary gear set achieves complex changes in gear ratios through a combination of sun gear, planetary gears, and ring gear, allowing the automatic transmission to automatically shift gears in various driving conditions.

Advantages: Compact structure, wide range of gear ratio changes, smooth shifting.

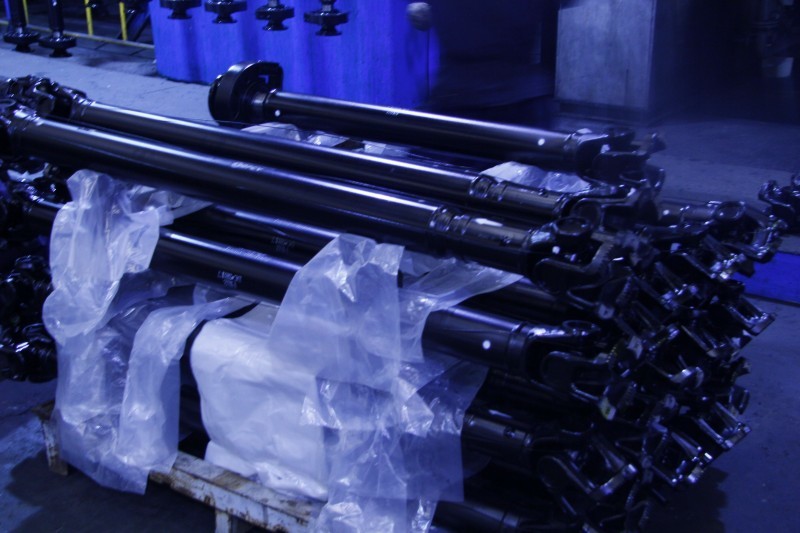

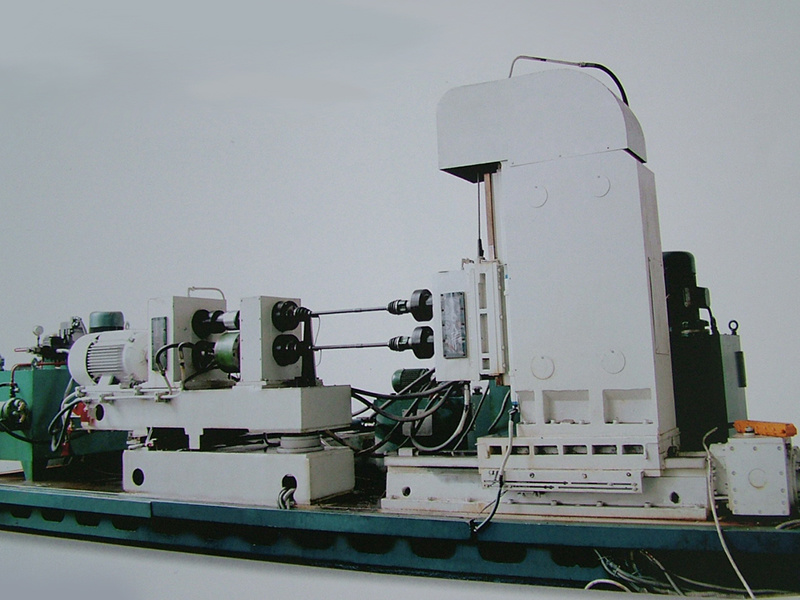

Our company has subsidiaries specializing in transmission shafts, aluminum alloy forging, cast steel, and precision casting. Our main products include transmission shaft assemblies and parts, forgings, large castings, precision castings, and aluminum forgings. We serve the automotive, construction machinery, agricultural machinery, and rail transportation industries.

Production Capacity

Engineering video 3

Engineering video 2

Factory video

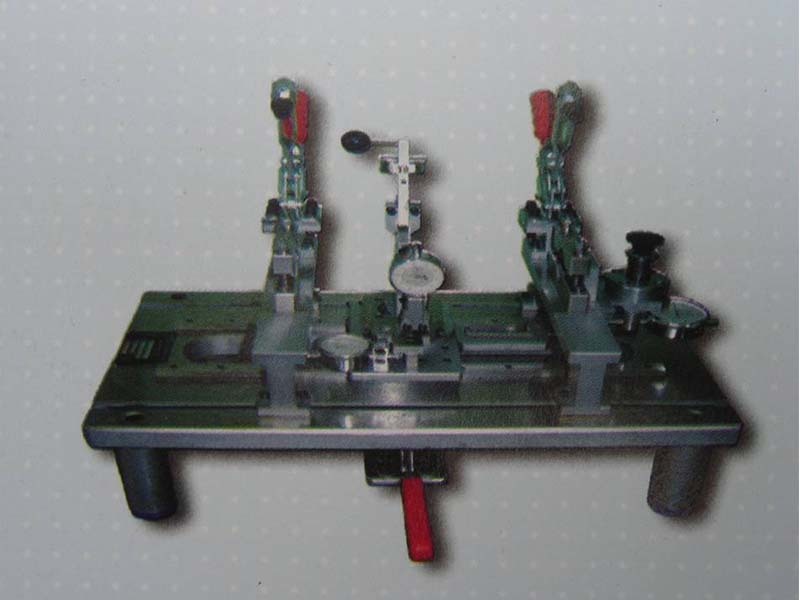

Quality Inspection

Related Products

Contact Us

Once we receive your message, we will contact you immediately and prepare a surprise for you.

Contact

Address:No. 226, Shuidu Avenue, Danjiangkou Economic Development Zone