Aluminum alloy forging

Category:

Aluminum alloy forgings are parts obtained by plastically deforming aluminum alloy material through a forging process. In the forging process, the aluminum alloy material undergoes plastic flow under pressure to obtain the required shape, dimensions, and performance.

Contact:

Product Details

Forged Aluminum Alloy Parts These parts are obtained by plastically deforming aluminum alloy materials through a forging process. They are lightweight, high-strength, corrosion-resistant, and have excellent thermal conductivity, making them widely used in automotive manufacturing. Below is a detailed explanation of automotive aluminum alloy forgings.

Material Properties

Low Density: The density of aluminum alloy is one-third that of steel, significantly reducing vehicle weight, improving fuel efficiency, and increasing range.

High Strength: After the forging process and heat treatment, the strength of aluminum alloy parts is comparable to some steels.

Excellent Corrosion Resistance: Aluminum alloys exhibit excellent corrosion resistance in atmospheric environments, extending the lifespan of automotive parts.

Excellent Thermal Conductivity: This helps dissipate heat from parts such as automotive engines, improving part performance and reliability.

Typical Applications

One-piece Wheels: Manufactured using 6061 and 6082 aluminum alloys, these offer lightweight, high strength, and superior surface quality compared to traditional cast wheels. However, due to higher manufacturing costs, they are mainly used in high-end passenger cars and commercial vehicles.

Control Arms: A crucial component of a vehicle's chassis system, these are manufactured using 6082 aluminum alloy. Forged aluminum alloy control arms are gradually replacing steel control arms and are widely used in mid-to-high-class vehicles domestically and internationally.

Knuckles: These are important structural components of a vehicle's front axle assembly and front suspension system. Aluminum alloy knuckles manufactured through the forging process have excellent overall mechanical properties and ensure vehicle driving safety.

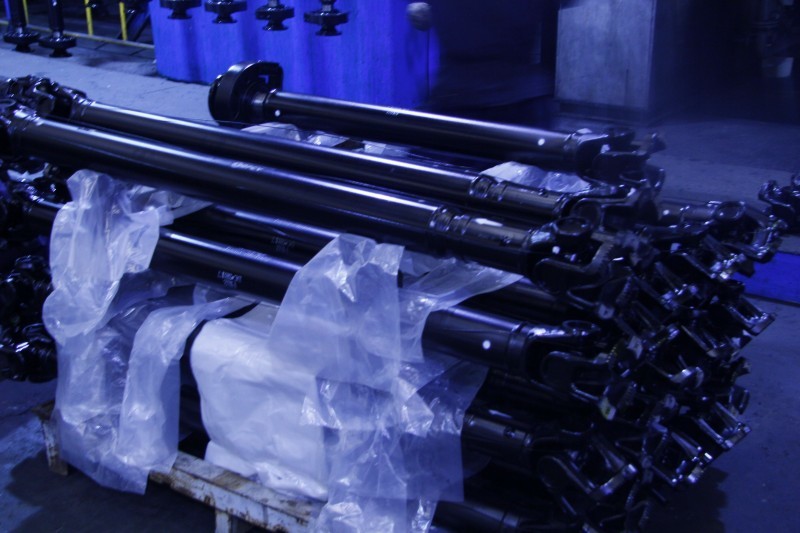

Our company has subsidiaries specializing in transmission shafts, aluminum alloy forging, cast steel, and precision casting. Our main products include transmission shaft assemblies and parts, forgings, large castings, precision castings, and aluminum forgings. We serve the automotive, construction machinery, agricultural machinery, and rail transportation industries.

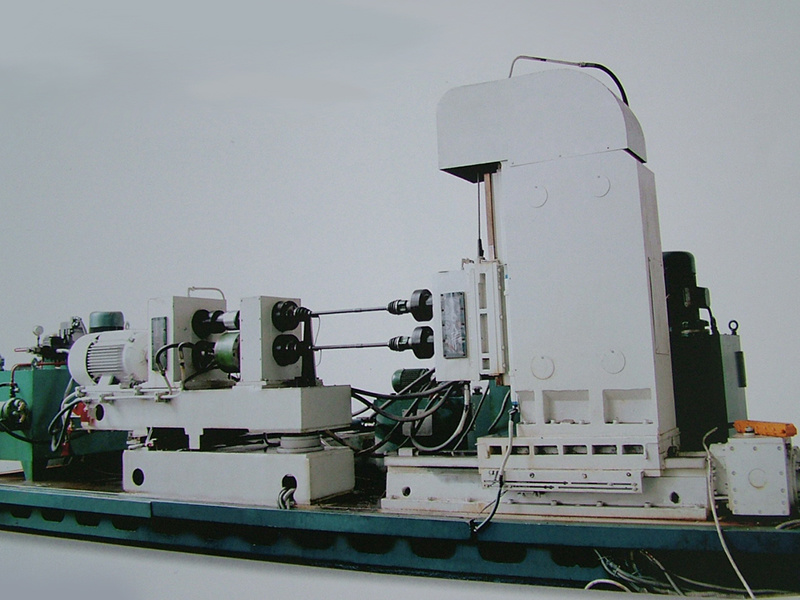

Production Capacity

Engineering video 3

Engineering video 2

Factory video

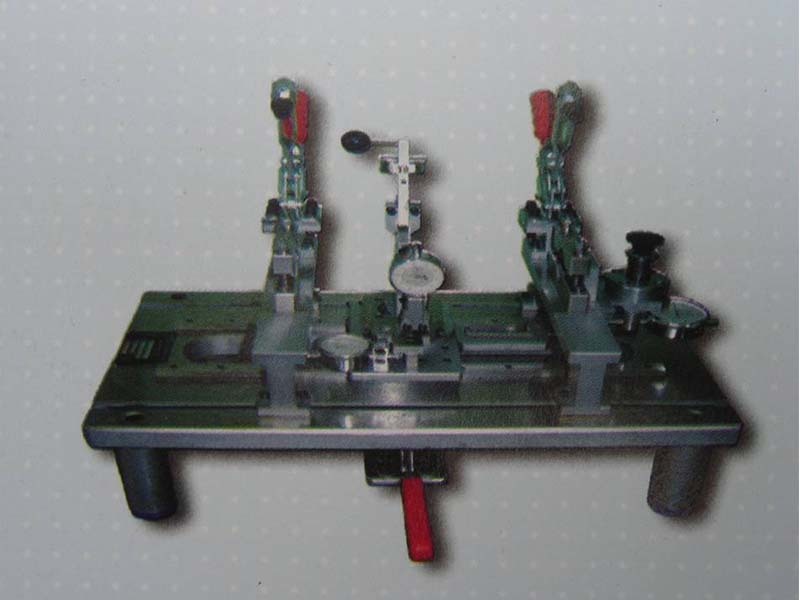

Quality Inspection

Related Products

Contact Us

Once we receive your message, we will contact you immediately and prepare a surprise for you.

Contact

Address:No. 226, Shuidu Avenue, Danjiangkou Economic Development Zone